Overhead Door Spring Risks

The boring facility stuff usually causes the biggest headaches. Overhead facility doors are no exception. Some have rollers but others operate with a custom guide and almost all overhead doors have a counter balance spring. In some cases, multiple springs. Sam Dorfen was dealing with the first type. Sam lifted his facility overhead door for the company vehicle to roll into. It was the same thing he had done hundreds of times before every morning. Except today instead of the door going up, Sam heard a snap. Suddenly, the door was rushing down! Sam had enough sense to move himself and his foot out of the way. The door slammed shut with a loud, metallic thud on the cement! When Sam tried to lift the door again, it wouldn’t budge due to weight. The culprit was a broken tension spring set that finally snapped. Once broken, the entire weight of the door was free, and gravity took over.

How Counter Balance Springs Work, and Fail

Counter balance springs are a common load handler on most overhead door designs. They are durable, last a long time, and the spring can carry a heavy amount of weight. But when those springs go out, there’s almost always no warning. The coil snaps, and the full weight of the door moves with gravity. Sam was lucky to avoid injury. A full door weight can cause a serious, crushing hit on someone’s shoulder, leg or personal property. Body parts can get caught in the way when the door comes down. So, door spring installations happen in sets versus an individual unit to reduce risk. If one spring breaks and they are the same age, the other spring(s) is probably not far from breaking as well.

Symptoms of an overhead door about to go out include different behaviors. Straining metallic noises and resistance to a smooth operation are two of them. The door suddenly feeling very loose in the lateral movement is another. A door being stuck in down mode and can’t be lifted without significant effort also happens. However, a spring about to break can’t be predicted. However, minor deficiencies in the door operation can lead to added stress and a spring snapping. And once this happens, it’s a good idea to examine the springs along with other potential causes for a deficiency.

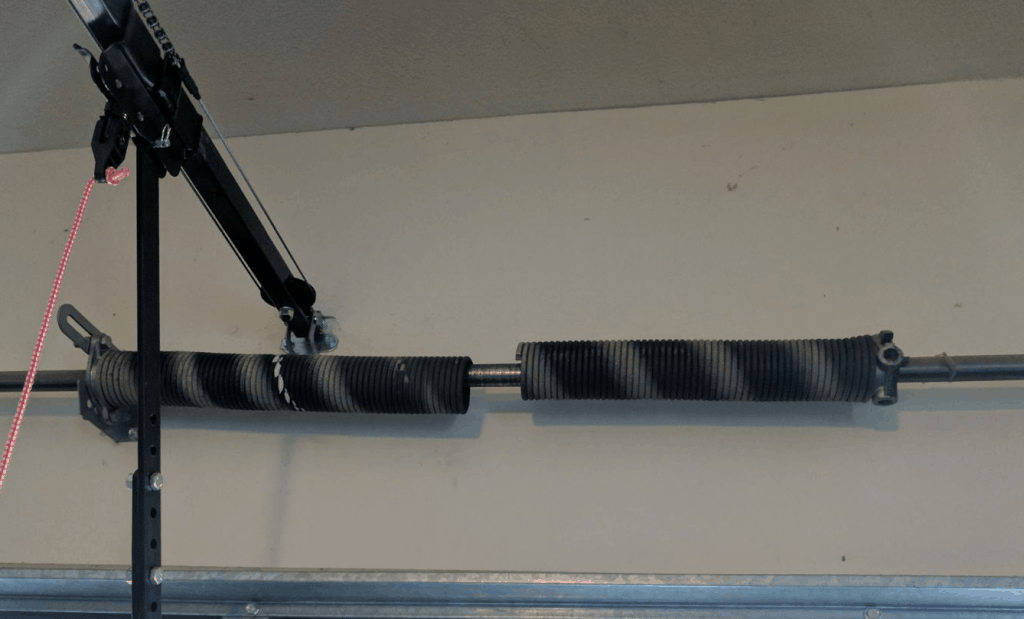

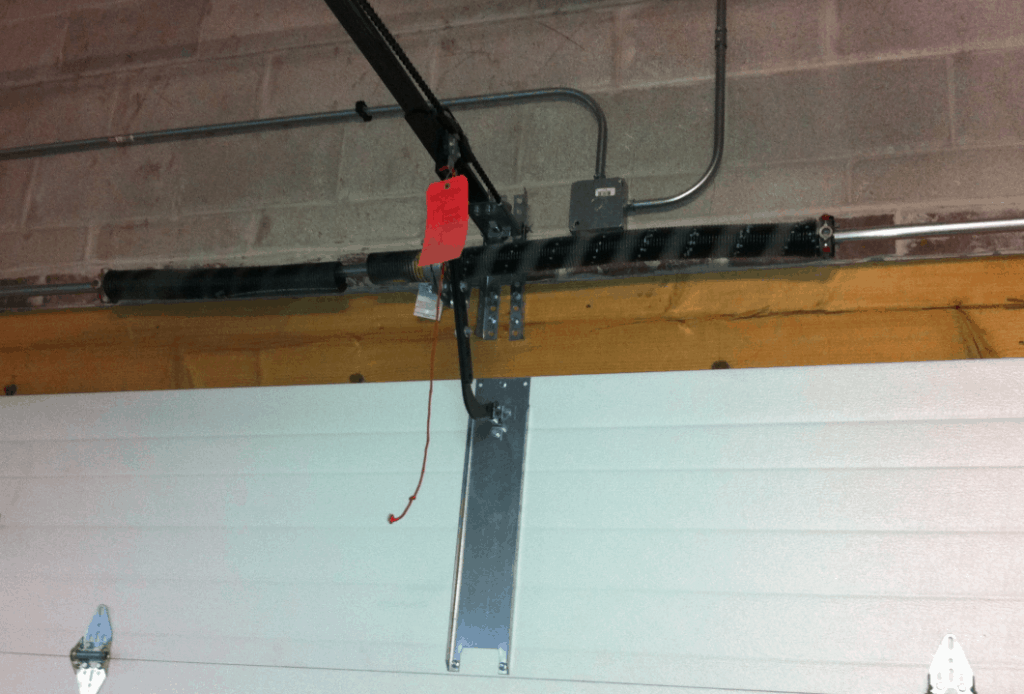

Large gap indicates a broken spring.

Springs should not hang unevenly.

Getting Ahead of the Curve Before the Snap

Dillard Door has been in the business of helping, installing and maintaining facility operation doors for clients for over 70 years. The spring failure scenario is a common one. It’s also a frequent surprise, but the spring failure can be delayed with preventative maintenance as well as starting with quality equipment. At some point every facility bay or garage door is going to have mechanical issues. That said, on the spot door service can make a big difference for very low cost versus a full replacement repair. Minor repairs can lead to expensive repairs if ignored.

How does such good care occur? Just looking at an overhead door system is not going to find problems, like a flat tire on a car. Dillard Door technicians go through every working components of a garage or bay door to confirm it’s working properly. That includes every safety component, bolt, screw and roller. Sometimes all that is needed is a minor fix. Other times, it could be a critical part like a section, a slat, a hinge or roller. Service calls can be set up on regular intervals with onsite repair at the same time. It’s a smart, practical approach to stretching out the life of capital equipment on your facility.

Remember, Prevention is a Lot Cheaper

The biggest mistake a business can make with a bay or garage door is to wait for the problem to appear. By then the damage is serious and expensive. And that takes operating dollars away from your profit margin and business. And it could even result in very expensive property repair or medical bills for injured employees/customers as well. Don’t wait for your Sam Dorfen to get hurt by surprise. Partner with Dillard Door to keep your facility safe, operational and functional, allowing you to focus on your business instead.